(Continued from Part 1. This concludes the article.)

Rugged Construction

Given the materials at hand. and the other design goals, it was easier for me to produce a yagi antenna for UHF frequencies than a comparable moxon antenna. The build had to be durable, and not likely damaged by abuse or neglect in a chaotic environment. And it can be easily repaired in the field. Not ‘mil-spec’, but close enough. And consider that UHF is easier to contain in a valley that has a pine forest, so it is therefore less of a COMSEC problem when low power is used. And to keep costs contained, and production possible in an austere environment, using common scrap materials that are the lowest in cost, ease of manufacture, helps makes the build a sturdier yagi that performs predictably at UHF frequencies than a UHF moxon built with the same or similar materials. And the EWB yagi significantly exceeds the wide-band attributes of the moxon.

Adequately Compact for Portable Work

While 1/3 larger in size, in comparison to a moxon, it still acceptably compact and rugged enough to be used as a portable, or at a base station antenna. And it duplicates the wider RF footprint that makes it easier to use as a part of a community communication effort. A narrow RF footprint can be too narrow and difficult to point, whereas the larger RF footprint can include several stations, and yet be pointed away from a station.

If I were using GMRS for a security operation, I would prefer to use a 5-element (or more) yagi that not only has a narrower footprint. But more importantly, because it has a higher front-to-back (F/B) ratio that sends more of the RF forward, and less to the rear. Yet a 3 element yagi has a suitable RF footprint for my AO, and is the superior choice over an onmi-directional antenna for such purpose. And as I mentioned before, it can be used horizontally polarized to reduce (attenuate) the signal that goes out the back to nearly match the moxon F/B ratio, should the moxon be vertically polarized.

The EWB yagi is an attempt to engineer a good all-around tool, and engineering anything is a series of compromises that hopefully results in a balance of attributes that produces a tool that meets a design goal. It has got to be practical. I’m not an RF engineer, but I do like making stuff work.

The EWB/UHF Yagi Design In Contrast with Commercially Produced Yagis

Yagi antennas from Arrow Antenna and some other suppliers, are not particularly expensive. These tend to be made entirely of aluminum, and are very lightweight, and are usually designed to have the highest gain possible, and have coverage of a single band, most often, a Ham band. However, not just to avoid the cost, I prefer to make my own, and make several of the same antenna at the same time, that are quick and easy to construct with simple tools and common materials. These should be easy to repair, and made to be rugged, though decidedly not ultra-lightweight.

‘Lightweight’ is a relative term used often in the military. Their definition of what is lightweight applies here. Given these attributes, the EWB yagi is best suited for austere environments. It is multipurpose, not only terms of the number of frequencies that it can be used for, but it also has the ability to be deployed in several roles. It is also light enough and compact enough (16″x 14″) to be considered ‘portable’. It is a durable and serviceable design that can be used in combination with common and uncommon transceivers. It is cost-efficient, and utilitarian. Other construction materials that can be used. The important materials are wood, aluminum, painted or galvanized steel, and copper.

A Cost-Effective Design

Not only did I avoid purchasing an antenna, but the resulting antenna is also essentially 3 to 5 antennas in one. Thus, I avoided the expense of buying 3 to 5, 40-foot lengths of expensive BR-400 (an equivilent to LMR-400) cable, as well. Now considering that the parts to make the UWB/UHF yagi were less than $5, I consider this yagi to be a bargain that would be hard to beat, because it’s ‘ultra wide banded’ ability and the use of common materials.

But how is the yagi built?

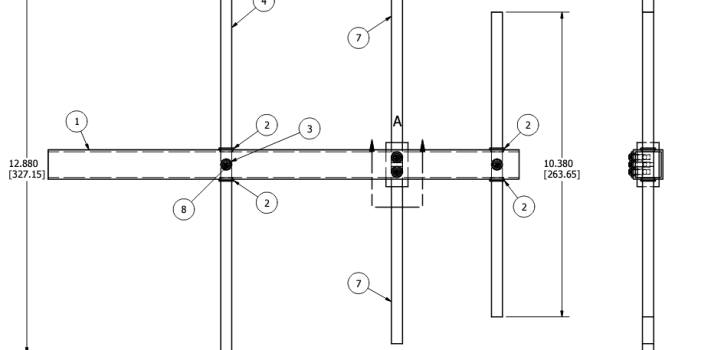

To better understand the EWB yagi, examine the plans for a 3 element GMRS yagi in the PDF at the N1TK web site. I’m indebted to Jeffrey Bail — call sign N1BMX — for this great data and illustrations.

The following discussion covers the materials used, and the modifications that produced a similar yet very different antenna from that of the GMRS only yagi detailed in the PDF. If my plans are unintelligible, then we can at least use Jeffrey Bail’s PDF of well-presented plans and ‘blueprint’ to make a GMRS yagi, or to assist in the building of the EWB yagi. Refer to the illustrations to see what it looks like, and how it might propagate.

Cutting Costs, Wood Beams and Common Materials

While I cut costs by using custom (home-milled) Western Larch wood for the beam, 1.75″ x .75 x 40″, and a collection of different scrounged materials for the elements, with these and other parts, the antenna usually performs as well or better performing than commercial antennas. I have yagis made years ago with wooden beams that are still straight and intact after more than 6 years of being in the weather. Larch is a good inexpensive wood for this purpose.

My favorite kind of insulators could be different kinds and sizes of poly pipe, or other non-conductive material except PVC. Certain manufacturers produce PVC that conducts electricity. Without a microwave oven to test the PVC, it is difficult to determine which do, or do not, until of course the antenna has been assembled and is tested. Therefore, if you’d like to use PVC, then place a chunk of the at pipe in a microwave set on high and attempt to heat it up. If it does not heat up at all, then it is not electrically conductive and can be used for making antennas. And make sure that any spray paint used to camouflage an antenna does not contain metal particles. I’ve had good results using Rustoleum brand paints that are marketed as no shine camouflage paint. Test the antenna before and after painting as the paint can lengthen the antenna electrically and effectively ruin it.

My Prototype

In this instance, 1/2 inch pex pipe was used to insulate aluminum and steel tubing with an outside diameter of 0.5 inches. The prototype antenna used a driven element that was salvaged aluminum tubing. 1/2 inch painted mild steel tubing was used on another driven element and the other elements. If 1/2 inch copper pipe that has an outside diameter of 0.625 were used, 1/2 inch black-color poly pipe, sold as drip line, has an inside diameter of 0.60 inches and can be used to insulate 1/2 copper pipe.

Regardless of the different materials used, the method is essentially the same. The elements are coated with flux (a paste used in soldering). Or general purpose grease could be used as a lubricant. The flux works best. The pipe and the element are then heated gently at the same time. When the pex pipe becomes soft enough, but not too soft, the pex pipe slips over the element to be placed into position that is in the center of the element. I used a 1/8″ thick rubber grommet between the driven element halves to keep them electrically separated. A two inch in length section of pex pipe, after it cools, contracts like shrink tubing, and is semi ridged. It firmly holds the halves in alignment.

Two brass machine screws and four brass nuts are the most expensive parts of the antenna. These are purchased new, or we can use common wood screws with a washer just as well. These are the contact lugs for a direct connection for the cable. Later, the connection will be encapsulated with a high grade automotive sealant and adhesive silicone to prevent corrosion, and water infiltration into the cable end. Appropriate length wood screws hold the elements securely to the wood beam. It has rock-solid feel, and will hold its shape even when miss-handled, or stored incorrectly.

Important Specifications for Wide Band Antennas

Here is one of the secrets behind this antenna, and other broad-banded antennas. By using a larger in diameter element of 0.5 inches rather than a 0.125 inch solid rod, and increasing the length of the driven element 1/2 inch for total length of 12.85 inches, and lengthening the reflector to 1/8 inch longer than the design example in the PDF, it has a much broader bandwidth. The positions of the elements are the same.

As a general rule, the larger in diameter are the elements, the better the interaction between them. This is the primary way to increase the bandwidth. Lengthening the elements also increases the bandwith down into the 70cm band and lower. If an antenna can be used on two radio services rather than one, then we need only one antenna, and one cable instead of two. In this case, we got three and more radio services, and more places in the spectrum that might be quiet. Yet there was more needed to further increase the bandwidth of a this antenna.

Browning BR-400 — an equivalent to LMR-400 — coaxial cable was used, and an air choke of 4 turns of BR-400 that are 5 inches in diameter, flattened the SWR as well. Small changes can affect the performance of an antenna. The RG8x did not contain the UHF RF (radio frequency) nearly as well, and caused the cable to become a part of the antenna, de-tuning it. Always check an antenna’s SWR after installation, as well. Testing was performed with the antenna at the height it will be used, and at least several wavelengths from any object that would couple with the radiator (the antenna), or reflect the RF back to the antenna, altering its SWR, to its benefit, or detriment. Test the antenna with a good quality VSWR meter, and keep it a minimum of 6 feet from any object, including yourself.

The wood beam (the boom) is 40 inches long and half of that length acts as a counterbalance. It could be cut to 16 inches in length for handheld operation. The antenna will pivot on a single heavy-duty lag bolt, just off center, so that the front is heavy and tends to point downward. Or a U-bolt can be used to secure it to a pole. A U-bolt is more costly and might not be available, yet with it, the height is easier to adjust. If it will be mounted horizontally polarized, it is best to use a u-bolt, but the beam could be drilled and a lag bolt used. Mine are pre-drilled for any mounting situation.

Cordage attached to the rear, or to the front of the beam, can control the angle of the yagi relative to the ground and horizon. Adjustment can occur without much effort from the ground, and while conversing with the receiving station. This is done so that one can quickly and easily adjust and reduce the RF footprint, and limit the range by allowing the antenna to point into the ground and just in front, or not beyond the receiving station. Conversely, the rear of the antenna points above the horizon and away from potential receivers to the rear.

Each element has an outside diameter of 0.50 inches

Here are the lengths of the elements:

Reflector: 13 inches

Driver: 12 13/16 inches

Director: 10 3/8 inches

Spacing is measured from the center of each element:

Reflector to Driver: 5 3/4 inches

Driver to the director: 3 3/8 inches

Even if the yagi is not built to exacting measurements as specified in these plans, because the antenna is so wide banded, odds are high that the builder will be satisfied with the results, and have a useful antenna that he can duplicate for others, if further modification and correction are not made.

The Cost Savings of Building Broad Banded Antennas

If one paid retail, and purchased professionally made antennas, I’ve saved well over $3,000 making my own over antennas, last month. This cost of savings does not consider that these have been broad banded, and tuned to perfection, so that they can be used on more than one band, or up to 4 bands per antenna. Given the doubling or tripling of the utility of each antenna made, in a final analysis, the actual cost savings is a multiple of $3,000. You can save a ton and have some fun, and all the while solving a budget, logistics, and COMSEC problems.

Buy High Quality Cable!

I scrimp on most things, but I buy the best cable that I can afford. The most expensive components for these antenna systems would be the cable. I save money by using scrap materials, but when it comes to UHF frequencies, always buy the best cable possible. If two different brands of coaxial cable with the same rating are found, and one is much more expensive, then the expensive stuff is probably the best choice. Tightly woven copper outer shielding is the best. If uncertain about the quality of the cable found on eBay or other such places, the check the prices at BuyTwoWayRadios.com. They do not sell junky cable. You can buy a spool of 500 feet to get a price break. However to get the widest bandwidth out of this antenna, use only LMR-400, or BR-400 (Browning) and be sure to use this same cable to make the air choke already detailed.

Conclusion

Because I am a knuckle dragging guerrilla kind of radio geek, I cannot do all the fancy computer work to present a blueprint of any sort. If it would be easier for the reader to build a yagi only for GMRS, download the PDF and plans for this 3 element yagi. The difficulty level would not be too much for the beginner, if the builder used the materials for the EWB/UHF yagi. It would not be necessary to use expensive parts, but use what works for you, and learn by trial and error, if necessary. I would only transmit from a base station on a directional antenna of some kind. If you need to extend the range of your GMRS radio, then use a yagi instead of a high-power mobile on an omni-directional antenna. And use only the lowest power setting that makes the communication possible.

Plans and instructions on how to build a yagi for GMRS: https://www.nt1k.com/files/n1bmx-gmrs-yagi.pdf