In 2007, I began warning SurvivalBlog readers about global over-reliance on Just-In-Time (JIT) inventory management. This system — also called lean inventory management or kanban — was first developed by Toyota in Japan, in the 1950s. There, with largely internal chains of supply that were all clustered around the major cities on Japan’s largest island, Honshu, the kanban system worked with wonderful efficiency. Kanban soon branched out to the other three primary islands: Hokkaido, Kyushu, and Shikoku. Manufacturers were able to cut costs by keeping their parts inventory small, and placing frequent orders to their supplying wholesalers and component parts makers. Kanban became very popular in Japan in the 1960s.

The Japanese lean inventory way of doing business was so successful that it caught the attention of American and European efficiency experts. They soon adopted it, preferring to use the term Just-In-Time (JIT). The bean counters earned nice Christmas bonuses, and both CEOs and shareholders were happy with a fatter bottom line. By the late 1990s, in many industries JIT became the norm. Even in worldwide trade, kanban proved to be efficient, if allowances were made for the lag time created by transoceanic shipping. American companies also found lean inventory beneficial in states with outdated inventory taxes.

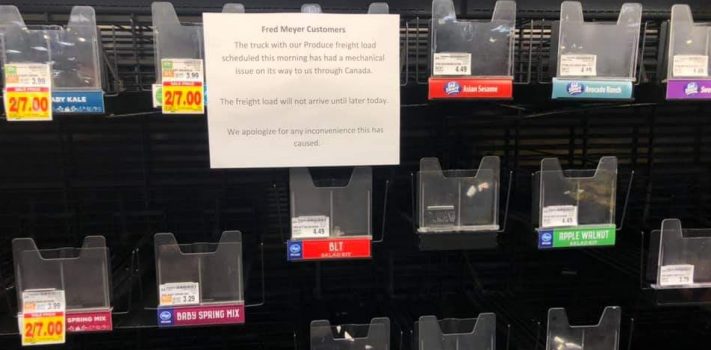

Seeing the success of JIT in industry, wholesalers and retailers emulated kanban practices. This widespread adoption was seen most dramatically in supermarkets. Most new stores that were built after the early 1990s omitted having a large rear storeroom for “overstock”. What you see on the shelves is all that they have available in the store. Increasingly, it is route drivers and jobbers from third party companies that actually stock supermarket shelves. This started first with bread shelves, but now entire swaths of store shelves are stocked by people who are not store employees. This shelf-stocking activity largely goes on between 2 AM and 6 AM every morning, so most customers are oblivious to this hum of activity.Continue reading“The Curse of The Cult of Kanban”