As the title indicates, my wife and I are outlining our family’s move to the American Redoubt. At this point, we’d already dug and poured the foundation and put in the walls of our log cabin. However, it’s not a log cabin without logs.

Unloading Logs

(Four hours were dedicated just to unloading the logs.) This required another piece of rental equipment called a lull. (It is a large fork truck that can keep level when it’s on rough terrain by tipping its shocks to compensate.) The semi-truck pulled up and parked 200 yards from the site due to the terrain not being drivable.

Unload the Entire Truck and Place on the Property

Bundle after bundle of sticker-coded logs were removed and placed at this site. This process took about four hours in order to unload the entire truck of stackable logs, windows and doors, beams, tongue and groove roof, tongue and groove flooring for the loft, and posts/beams for the interior of the log home. It was a surmountable amount of weatherproof packages to organize and place in the proper order of consumption on the property.

Stacking the Logs

(Stacking the logs took four weeks.) This was the fun part of the project. It was like building a large Link-N-Log home, as you men might have done as a boy. Each log came numbered/lettered coded and held its place on the schematic. The walls where in the proper allotment and would be stacked correctly and real soon. (I recommend stacking the logs as soon as possible.) We waited a winter, and though it is good for the logs to age a bit, they could split and crack to become unusable or, worse, their label could fall off and then you have no idea where its placement should be in the grand scheme of things. Thank goodness neither of those happened to us.

Log Stacked in Proper Position and Screws Secured

Once a log was stacked in its proper position, you noticed that between each of the logs were two groves extending the length and two pieces of rubberized tape would fill the grooves for a watertight seal. Next were the twelve-inch log screws, which were so tough they couldn’t be saw-zawed in half. After two strips of rubberized weather guards were placed onto the next log and screwed down to the log underneath, the schematic was consulted to find the next log placement. This process was followed and so-on and so-forth. The screws were secured on both ends of the log and at about every four feet in length.

Log Home Company Pre-Cut Logs

The log home company had pre-cut logs, allowing for the correct architecture of the home and openings for the windows and doors. In addition, only the windows and doors needed additional chainsaw work. (There is more on that below.) The rest of the home locked into place, just as our pictures depicted.

Doors and Windows

(It took three weeks to prepare the spaces for doors and windows.) After gloating over the finished product of all the logs being stacked correctly, and looking at it from all angles, next was building the window and door bucks. This was accomplished by utilizing 2×6 pinewood and constructing frames inside the log openings. However, the frame could be nailed at the bottom end but must have a two-inch gap at the top. This is because over the course of the build, log settling will occur over time.

Using a Chain Saw to Cut Into Logs

Use a chain saw to cut into the logs about four inches into the bottom log for the windows. For the doors, it was chain sawing into the tops of the logs about four inches. Learning a chainsaw was another facet to the project. It was to cut costs on labor and also for the thrill.

Beams and Posts

(We spent two weeks on the beams and posts for our log home.) This part was easy when you have the correct toolset in your arsenal.

Elevator Crank

Home Depot sells an elevator crank, which allows you to place a beam (balancing it perfectly in the center of the elevator arms), and turning a crank until the beam is in position. It will hold a heavy beam, high into the air, until you secure it into place, according to the blueprints. Once the beams and posts were all secured through placing the proper log screw size (either 6, 8, 10, 12, or 20 inch), it was off to a quick review of the plan.

Clean the Job Site

At this juncture, the job site was getting quit messy. So, I took some needed liberty to clean it accordingly.

Gables

(The gables required four weeks of efforts.) There were more to this than meets the eye. First, I needed to establish work areas. It needed to be long enough to encompass the entire span of the work area from one end of the gable to the other end. In other words, the gable needed to stretch from one end of the home to the other end. I chose the top floor where the loft area would be to set up for the work area. Next was planning which gables would be constructed and erected first, so I could hit all four of them without crowding one into place so you’d need a crane instead of just a push with your biceps.

Blueprints Were Clear

Luckily, the blueprints were clear enough. I could count the number of 2x6s that comprised each of the four gables.

Changes to Give Home a Cathedral Ceiling

Since it’s your own project, I did change the pitch of all four to give the home a cathedral ceiling when completed. A master builder was my neighbor, and I could run these ideas across for structural soundness when we thought about changing the plan. It would eventually look like a 1500th century Catholic Church dotted in Europe with all the beams and wood working. Now it really looks nice and is the signature feature of the log home!

The First Gable

After constructing gable scaffolding, and to push out the completed gables once they were completed to the edges of the home, I got to work building the first gable. It took extreme strength, on my part, to slide the first finished gable out, center it, erect it, and then secure it. It was a job well done when looking back on it.

The Fourth Gable

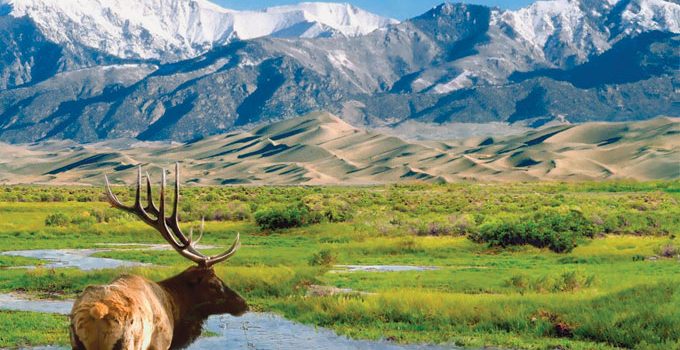

One, two, three gables built and now in place. The fourth one took a bit of effort, as it was to house the 7-foot x 2.5-foot picture windows, which gives us those glamorous views of the mountains. It was much heavier and had to be lifted over my head in open air of the two story great room.

I built a scaffold right into the logs with 2x8s and then nailed a bevy of 2x6s out stretching the entire span of open space. Once I pushed it out onto the scaffold, the base would catch the top edge of the last course log and push it up onto the top log. I had tied a rope to the top of the gable so it couldn’t flop over the other side of the logs and crash into the ground. All four were secure and nailed/screwed properly.

Recommend Placing Synthetic Tarpaper

Looking back on it I would recommend placing the synthetic tar paper on the outside of the gable’s OSB before erection. It would save time and effort in a later step, working off a ladder to do the same. Which is easier? The ladder should not be used!

Tongue and Groove Roof

(The work to build a tongue and groove roof required three weeks.) This’s something ingenious for log homes. The pine ceiling started at the bottom of the overhang being nailed into the overhead beams. One by one, each course was laid, and all the way up to the peak for each of the roofs.

Mechanism to Place Bundle of Wood Into Work Area

The key is to stagger seams so they don’t all line up on the same beam, as that gives more strength. In addition, have some type of mechanism to place a bundle of wood up into the work area you’re planning to tackle next. I used ropes, then laid the boards out first in a six row segment, nailing all rows into place in one fell swoop.

Roof Crown and Layers to Make Home Weatherproofed

The roof crown just needs to touch and not be sealed off at the peak. Remember this is the inside ceiling portion of the build and not the actual roof which will weather the storm. Eventually, there will be 2x8s standing upright on top of the roof and filled with foam insulation, then a layer of OSB on top of the foam, then a layer of synthetic tar paper on the OSB and then finally a steel layer encapsulating the roof. Now that’s weatherproofed.

The four other roofs were completed according to specification and now look just like the first one. The interior, with high vaulted ceilings and over arching beams now looks astonishing. It feels cozy at this point.

Stain/Log Jam

(This process of applying log jam required two weeks.) Next in the plan was sealing off the outside of the logs by utilizing a product called Log Jam. It comes in all assorted colors and themes. After utilizing a color palate and matching it to the liking of our logs, there was a process of caulking between the logs and any cracks/seams within the logs. The outside was completely sealed off.

Log Stain and Sealer

Next was the log stain and sealer. It’s best to go light for your first coat and then gradually go darker if needed for your next prescribed coats. Even the light stain was considerably dark. But just one coat is all you need to keep out the sun’s ultra violet rays and to keep the logs preserved from affects of weather. In another two years, is when you’ll add other coats.

Here is a hint: The lighter the color of stain, the less ultraviolet light that is blocked. So, add a second coat for those lighter colors to obtain a better preservation of logs.

The Log Jam calking was also used for the log seams inside the home. Be sure, whether inside or outside the home, when caulking to go from the top where the gable meets the logs right down to the bottom log where it touches the subfloor. Be sure that the log butts are also calked and any cracks (there will be many) are also sealed. Now that the seems are caulked and cracks sealed, the interior coat of clear log stain was added for protection and also to block ultraviolet rays which protrude through the windows.

Porch

(The porches required two weeks to build.) The porches were next on the radar screen to tackle. Another piece of rental equipment was needed. This time it was a post hole digger. It was a Bobcat, which held a one-foot in diameter drill bit needed to dig the seven holes into the ground. The seven sonotubes were placed into those holes and are cardboard tubular shaped structures, which protrude into the ground about four feet. They were leveled off to allow each one to be the exact height. I used a laser as well as a level to accomplish this feat. Next, I laid the anchor bolts out, one for each post, doubling them up at the corners.

Sonotubes Leveled, Cement, and Anchor Bolts

Once the Sonotubes were leveled accordingly, I filled them to the brim with self-mixing Portland cement in a wheelbarrow. (There was no need for the cement truck this time.) As the concrete hardened to a point of stiffness, but not totally solid, the anchor bolts were placed in at the intervals desired.

Sill Plate for Floor Joists

Again the anchor bolts would be used to secure the sill plate of the porch. That sill plate was used to nail the floor joists into, leveling at every step. Once the joists were secured, the porch flooring (2×6 pressure treated forms) were nailed into place.

Porch Beams, Roofing Trusses, and Ceiling

The porch beams were stained and cut accordingly and bolted in with upright leveling on each side. Then the roofing trusses were installed, which required a bit of wood working to carve out slots, giving the truss a correct angle according to plan. Once everything was leveled again and squared, the tongue and groove porch ceiling components were installed. Then the sheets of OSB boards nailed over the ceiling boards and with a last bit of effort, placing a sheet of synthetic tar paper to seal in the porch roof prior to the steel sheets being installed.

Foam Roof

(The contractor company required one day to complete the foam roof.) At this point the labyrinth of 2x8s are nailed into place on the roof completing nice 4×8 squares. Underneath that 2×8 maze, remember that you already completed the tongue and groove pine wooden ceiling and a sheet of synthetic tar paper stapled over top of it. Since this is the American Redoubt, there are weather elements you might not see in other parts of the country, such as massive/heavy-weighted snowfall in Montana, extreme high-powered wind in Wyoming, or rain/hail/sleet/snow and massive water gushing from the sky in Idaho, sunlight during long summer months, et cetera. You want to take every opportunity to safeguard from these elements as you continue your work efforts.

Working with the Foam

You will need to summon a foam truck to allow you to complete the insulation portion of the project. Spray about two inches of foam into the 4×8-boxed cavities, because that will expand to between six and eight inches in foam. Do not fill up the eight inches inside the box. Imagine that expanding to 30 inches of foam.

As a second option, you could fill the roof in with insulation by unrolling large rolls and cutting them at the eight-foot intervals. However, this avenue will not have the R-value that the same depth of foam will yield. For example, R-value for 6-inches of insulation nets about R-21, and R-40 is netted for the same depth of foam.

OSB Wafer Sheets

Once your foam is settled into the boxes, nail the 8×4 OSB wafer sheets over those boxed crevices. After that, you can walk on the roof for all intents and purposes. Now for safe measure, place a bead of caulk around all the cracks where the OSB wafer boards butt. Lastly, staple another synthetic sheet of tar paper onto the OSB. You would most likely place a string, winding through all the staples, prior to each staple placed. This string will give it strength and shield against any wind resistance for at least a few months longer.

The Fascia

Don’t forget the finishing touch. The 1x8s nailed around the perimeter of the roof as the fascia. It’s actually nailed vertically to cover the OSB sheets and outer perimeter of the 1×8 boxes just created in the previous step. For good measure, it is best to stain the fascia and be readied for the tin trim around the base of the roof prior to securing.

Tin Roof

(Our tin roof required nine days.) The log home roof is probably the first thing someone would notice for a split second sooner than shinny pristine stained logs. Since this is going to be a signature view of the home, it’s best to get the color of the tin correct. Use a website, which you can choose color for the tin against the color of stain you’re utilizing for your logs. There are many websites out there, so just do a search on one you would like to utilize. In addition, you would need to find a company to produce your steel sheets in the color of choice. The norm is to call it tin, but really it’s steel.

Relay Measurements to Manufacturer

In order to relay your measurements to the manufacturer of steel, perform all your measurements on the roof from peak to bottom edge, and then the entire width of the roof. Give yourself about a two-inch overhang. Don’t forget about if you have eaves, peaks, ridges, hips, valleys, gables, and dormers—they also need to be accounted for. The company you select should be able to assist you in those measurements and may need a few pictures of your roof to help you identify them.

Weeks to Have Roofing Sheets on Job Site

Once the order is placed, it would take about three weeks to have your steel roofing sheets on the job site with correlating screws, rubber tape, flashing, peak vents, and trim. The screws should have rubberized grommets under their head in order to allow for temperature tolerances in cold winters and hot summers. (It allows the steel to move a bit during temperature fluctuations.)

Roof Assembly

Once the shipment arrives, the roof assembly is really easy from the steel sheet aspect. Once you have a system in place of lifting the steel sheets onto the roof, it’s a matter of ensuring the overhang is established correctly (about two inches), and then screw down the first sheet as you square it. All other sheets placed should have a rubberized tape to seal in between each successive sheet as you screw right through the ridges. Placing about five screws in rows about 18 inches apart, your sheet should be secure to withstand TEOTWAWKI. Be sure that the rubber grommets under the screw head is not tightly screwed down, but left a bit spongy to fluctuate in the advancement of heat or cold weather. Any cutting of these steel sheets would be done with a circular saw and special blade given to you by the manufacture. You should have no issues with the cuts.

Peaks

Once the large steel roofing sheets are screwed into place, which may take about three days for this task, it’s time for the peaks. There are strips of steel with tiny air vents inserted that need to be screw down to both sides of the peak to encompass both sides of the steel sheets you’ve just completed. Another tool in your arsenal that should be well used by now are tin-snips.

Bottom Trim

As you step back, you might pat yourself on the back, looking at the watertight and weatherproofed roof, but your eye catches that something is missing. Next is to add the bottom trim around the entire wooden fascia. Again tin-snips are your friend. You need to use them to snip the correct length and to create the correct flare for around corners where two pieces abut. The same type of rubberized grommet head screws will be used to secure the trim, but they are a little longer than the ones you used for the roof sheeting.

See Also:

- 1 – A Memoir On One Family’s Move To The American Redoubt- Part 1, by X. Liberal & China Doll

- 2 – A Memoir On One Family’s Move To The American Redoubt- Part 2, by X. Liberal & China Doll

- 3 – A Memoir On One Family’s Move To The American Redoubt- Part 3, by X. Liberal & China Doll

- 5 – A Memoir On One Family’s Move To The American Redoubt- Part 5, by X. Liberal & China Doll (Active 6/20/18)

- 6 – A Memoir On One Family’s Move To The American Redoubt- Part 6, by X. Liberal & China Doll (Active 6/20/18)

SurvivalBlog Writing Contest

This has been part four of a six part entry for Round 77 of the SurvivalBlog non-fiction writing contest. The nearly $11,000 worth of prizes for this round include:

First Prize:

- A $3000 gift certificate towards a Sol-Ark Solar Generator from Veteran owned Portable Solar LLC. The only EMP Hardened Solar Generator System available to the public.

- A Gunsite Academy Three Day Course Certificate. This can be used for any one, two, or three day course (a $1,095 value),

- A course certificate from onPoint Tactical for the prize winner’s choice of three-day civilian courses, excluding those restricted for military or government teams. Three day onPoint courses normally cost $795,

- DRD Tactical is providing a 5.56 NATO QD Billet upper. These have hammer forged, chrome-lined barrels and a hard case, to go with your own AR lower. It will allow any standard AR-type rifle to have a quick change barrel. This can be assembled in less than one minute without the use of any tools. It also provides a compact carry capability in a hard case or in 3-day pack (an $1,100 value),

- Two cases of Mountain House freeze-dried assorted entrees in #10 cans, courtesy of Ready Made Resources (a $350 value),

- A $250 gift certificate good for any product from Sunflower Ammo,

- Two cases of Meals, Ready to Eat (MREs), courtesy of CampingSurvival.com (a $180 value), and

- American Gunsmithing Institute (AGI) is providing a $300 certificate good towards any of their DVD training courses.

Second Prize:

- A Model 175 Series Solar Generator provided by Quantum Harvest LLC (a $439 value),

- A Glock form factor SIRT laser training pistol and a SIRT AR-15/M4 Laser Training Bolt, courtesy of Next Level Training, which have a combined retail value of $589,

- A gift certificate for any two or three-day class from Max Velocity Tactical (a $600 value),

- A transferable certificate for a two-day Ultimate Bug Out Course from Florida Firearms Training (a $400 value),

- A Three-Day Deluxe Emergency Kit from Emergency Essentials (a $190 value),

- A $200 gift certificate good towards any books published by PrepperPress.com,

- RepackBox is providing a $300 gift certificate to their site.

Third Prize:

- A Royal Berkey water filter, courtesy of Directive 21 (a $275 value),

- A large handmade clothes drying rack, a washboard, and a Homesteading for Beginners DVD, all courtesy of The Homestead Store, with a combined value of $206,

- Expanded sets of both washable feminine pads and liners, donated by Naturally Cozy (a $185 retail value),

- Two Super Survival Pack seed collections, a $150 value, courtesy of Seed for Security, LLC,

- Mayflower Trading is donating a $200 gift certificate for homesteading appliances, and

- Two 1,000-foot spools of full mil-spec U.S.-made 750 paracord (in-stock colors only) from www.TOUGHGRID.com (a $240 value).

Round 77 ends on July 31st, so get busy writing and e-mail us your entry. Remember that there is a 1,500-word minimum, and that articles on practical “how to” skills for survival have an advantage in the judging.

Sure this is nice house. He’s had teams of workers crawling over the place plus he’s left records all over (lumber yard, roofing vendor, etc). Let’s not kid ourselves this a secure retreat location. Just horrible OPSEC.Everyone in the county will know about this place.

Sour grapes? Look, I’m no contractor, and the last 2 installments have had my eyes glazing over, but, to me, your comment comes across as wanting to criticize that which you’ve failed to achieve yourself. Those who can, do. Those who can’t, find reasons to criticize those who can on the internet.

I tend to agree with your comments here, Jason. I think OPSEC is a bit of a over-hyped idea and is taken to extremes. As an example, in the context of this story and OPSEC as it is typically discussed, this suggests that a couple from CA has moved to the redoubt and they need to maintain 100% OPSEC because why? Because they think people in the redoubt are going to attack them in a crisis? Does not this idea directly conflict with the entire premise of the redoubt?

Further, prepping is a mainstream act. Many people from all walks of life seem to participate in some fashion. Complete and total OPSEC is only fooling one’s self. Go talk to your neighbor, they share similar concerns as you.

Cut him some slack, it’s not like the existence of a structure, absent any other info, is essential to keep totally secret.

Pretty much my view as well, I voiced it on day 1 when I asked about cost of land, … My reply didnt get posted,…. What people don’t realize is that large 18 wheeler trucks delivering excavating equipment and building materials to remote locations just screams ” Im building a home out here!” And thats ok.. but claiming OPSEC??.. City slickers moving here have a lot to learn about the redoubt area..

I believe Hugh answered your question succinctly. Also is in the Redoubt, we have neighbors as like minded as us and they too had trucks / maybe workers to enter their property in build phase. Unless you’re the Unabomber sneaking into BLM land in the night on Christmas Eve to erect a makeshift cabin you’re going to have some wake in your comings and goings. Yes people have to live their lives and all of us have been seen leaving and entering our properties. No one is total OPSEC. No one with a normal family life here.

They’re from California and as much of that state is rural as the midwestern states. We don’t know they’re “city slickers.” Just saying. Good post and waiting for tomorrow.

Anonymous, it’s a house not a nuclear bomb shelter. At this point it is just a rural house.

My wife and I were in our mid-60s when we did the same in Montana. We (like Jason) are what this old coot calls ‘AmeriCANS’ in a country full of ‘AmeriCANTS’.

Why not play up the great detail he provided the rest of us? No need to slam him for being thorough. If you think for a minute that any of us have privacy you’ve not been in the .gov world at all………….let’s keep things professional, civil and ‘nice’ in our forum here please. I continue to ask HJL and Jim to consider this article for the top three this round. It’s greatly detailed and offered to the rest of us humbly. Let’s reciprocate in grace please.

It’s quite apparent you have never been around building. From your description of how you did worked you did note plan ahead of time on the next phase. It’s sound like you did well for a green horn.

I spent over 30 years in Alaska building many types of homes and shops. I was fortunate to have grown up and worked for contractor as a young man in the building trades. Working in cold and windy place has it’s challenges. My last place I built we could get up to 8o mph winds in the winter. We screwed out metal roofing every 12in. along the edge of the roof to keep the wind from getting a chance of lifting an edge. It only take one time for the wind to lift it and the whole roof is gone. I wish you well on future projects as you have some experience under your belt.

Don’t worry to mutch about anonymous. We had the Arkansas National Guard stand up our timber framed basement wall !

“…… look like a 1500th century Catholic Church….”

Wow! That must be some futuristic design!! ((wink!))

Otherwise, sounds like an awesome house. Once you’re finished, I’m willing to wager it won’t take much to keep it warm in the winter. Congratulations!

Great article! I agree with Scott this should be in the top three articles this contest period. Where are the pictures that have been mentioned?

Just_AC

@Just_AC

Sadly, most of the pictures that were sent in with the article are too small to be used and have been left out.

First, I think the guy doing this is commendable. Second, no one here can judge whether I’m a wanna be with sour grapes or not. I may be the most prepped up person on the planet. My point is — unless he’s very careful — in a crisis people will be going “Remember that house we worked on for that prepper dude?” Especially if he puts in special elements like ballistic glass, large water tanks. If he does that it would be good to hire contractors from outside the area. Even without a crisis local no goodnicks will see a new house and think they have money.

This is wonderful, commendable, may more right minded people move to the Redoubt — and not saying if I’m there or not. G-d bless all of you.

I believe this article helps people understand the home building process from an inexperienced viewpoint which can be very helpful. Every one of us has knowledge and experience with some aspect of life and living. It seems few of us step outside that comfort zone. This shows all of us we can do it.

I have been a contractor for 40 years and built hundreds of homes in 3 different states. Many of them log structures. All of these processes I perform every day. So I can say there s much validity here. This article explains each stage in clear language. Also the time frames required for each stage may help others with planning. Good work. Love your home!

I have a question for all the individuals that have built similar structures.

Will your retreat be 100% self contained, meaning you produce everything you need.

In the belief of a total collapse of society than the transportation of goods and services will be a thing of the past.

How can anyone or even a group survive long term?

Lastly, these Outpost will be known to many when food runs out just like in the book Patriots. It will not be like the 1800’s farming but more like Mad Max

Hey Skip, I will jump in here and attempt to address your question. I have not attempted to build a structure like the one mentioned in this article. I have, however, been to several retreats/farms and bunkers that attempt to be “sustainable”. I have yet to meet a person that can meet 100% of their needs off grid. I have talked to people that come close, but mostly people like the idea of being 100% off grid. Few to none actually meet their own needs.

How can anyone or a group survive long term? The best way I have found is primitive skills and knowing your environment. What I mean by knowing your environment is when we think of resources, typically how that word is defined is by corporations through commodities that are more efficient to produce. So, the word resource has an economic component that the average joe misses. To understand your environment is to consider what types of “wild” foods are available in your region. Once you understand the abundance of food (depending on what region you live in) that is “wild,” nature will begin to take on a whole new meaning. This will also inform you to where animals frequent for hunting or trapping.

Also, Mad Max is a fictional movie. Resource conflict and research that critically understands resource scarcity shows that people are less violent during times of food shortages. The idea that people will become more violent is based of Malthusian narratives that have been used for political reasons since Thomas Malthus put forward his idea of resource scarcity. This may shock some of you, but there is more evidence that people come together during hard times than there is about a mad max world taking place. Sure, there are short term issues, I am not debating that. But, long term….there is no real evidence.

I have often thought the same. That people come together in rough times. You here many Depression Era stories of cooperation. I have read references stating that the Wild West actually had very little law enforcement and very little crime. Neighbors needed each other and feared being ostrosized for bad behavior more than actual violence.

The information out of Venezuela seems to indicate they have had a rise in crime during their troubles. I am not sure if that indicates that my theory of cooperation is bogus or just varies under different circumstances. I would say that we may only be hearing one side of the story. I suspect there is a fair amount of cooperation that is not reported. There may be differences between rural and urban areas. The government is actively preventing people from helping themselves in many cases. Hard to say.

Back to the Depression Era. When we entered the Depression it would appear we had a pretty firm set of Judeo-Christian values in this country. I say appears because the 20s were marked by a lot of debauchery and who knows for sure how deep those values ran. But if we assume they did dominate society more than today, would people today stay relatively peaceful like they did back then with all those values heavily challenged right now? Hard to say. Also the Depression though tough was not teotwawki. The economy still functioned and IMO without all the government help from Roosevelt would have recovered pretty quickly.

Just my random thoughts from reading your comment.

To JBH, the recent situation in Venezuela is tricky but certainly interesting. One thing about Venezuela that seems to mimic most civil unrest and society issues is that government policy plays the largest role. It is safe to say that crime is up in Venezuela, and most (not all) of the violence looks to be between the government and the populace. I have yet to see a story about the impacts of rural living in that country, other than just mentioning food issues. The American media is always framing the events in Venezuela as happening due to socialism and because of that I think it is important to be mindful of that framing for us survival minded people interested in watching how issues play out in other parts of the world. This is what I meant in my other comment about Malthusian narratives being used for political purposes.

Let us also consider how North Korea has been the bad guy for several decades, and it seems because there may be a possibility of Mcdonald’s and hotels entering the North Korean market, it will be interesting to see if North Korea starts to be framed as a friend in American media. I have seen a few articles that are already starting to paint this picture. Peace through Big Macs! Maybe we can expect the North Koreans to go from starvation and malnutrition to becoming obese diabetics? Great discussion and I really enjoyed your comments.

Some things you just can’t hide, so OPSEC on them you don’t worry about. I had to buy a 10′ tunnel boring machine for my bunker, so somebody’s going to know! The thing is, “where did I use it?” As long as that can’t be found, my OPSEC is fine. The only people that know are the stone company and concrete company, and they don’t know where the stone came from, and where all the gunnite went. All they did was pick it up, and drop it off.

If more than one person is invovled in your project opsec is a complete myth. About the best you are going to do is stop an internet troll or a common criminal from figuring you out on the internet.

You will not be able to stop the government from knowing exactly what you are doing ever. Hell the british were hunting down ships from france on the open ocean on the other side of the world long before technology we have now.

Our government records every phone call, every money transaction, every picture, your dna, your associates, your purchases, your intelligence level, your earning potential, all your internet traffic and the use cell phones to pattern where you go…. and where people that know you go and what they do…. Saddam could not hide with billions of dollars and 1000s of people helping him… they government can pattern your life and your families life and the can guess with great accuracy about your plans with the knowledge about you that they already have at the push of a button…

Yes and England had the mightiest military in the world. Yet they were beaten by AmeriCANS with muskets.

And the United States had the mightiest military in the world. Yet they failed to win the war in Iraq (and every other small country) for the last 73 years.

Never forget retired career Army officer Bill Buppert’s Law of Military Topography: “Mountainous terrain held by riflemen who know what they are about cannot be militarily defeated”.

Question. Looking at the time required for this project. Could the author indicate at least roughly (understand his OPSEC concerns) what he and his wife were doing to make a living during this time? Did they have money saved and devoted full time to this project? I had a neighbor who took a year off from his house painting business and worked full time building a house while his wife continued working as a nurse. Did this gentleman do something like that? Did he work at his regular job in spurts and work the house in spurts. Do these times reflect working in evenings an weekend while working full time?

One thing about ‘Preppers’ as presented in current media and literature is that they tend to be upper middle class with sufficient disposable income to purchase new materials, purchase raw land and pay the cost of construction. By the time many of us get to the point in our lives where we can locate to RD or other similar locales we are at a life stage where we have maintained homes for decades and are not eager to take on that type of responsibility over again. As a retired urban planner from southern California I would be more inclined to buy a lot of about 1 acre to have a family garden, be located in a town or close to a state road and would purchase a modern (not older than 15 years) modular pre-fab home. Security is a concern, but you can only do so much in the age of drones that can see, hear and destroy from miles high in the sky. OPSEC is obsolete in my view. I also don’t care for snow and long winters so the desert southwest is where I will be.