About four years ago, my wife and I finally got all four children out of the house and “on their way.” This allowed the two of us to pursue our dream of “leaving the city” and moving to a “rural homestead” on the edge of Middle Tennessee. The property we settled on is a modest five acres nestled within miles of rolling hills and cave fed streams within each “holler.” It included a 1940s farmhouse, two streams, a springhouse and a no-longer-used capped well casing. We managed to fence the 3-1/2 acre hill and stocked with Great Pyrenees herding dogs and a small herd of goats. We also dove into raising chickens.

To support our new collection of livestock, we constructed a small barn and fed a watering trough via roof gutters. This water source worked well for all the animals except in the hot summer months of July thru September when the rain slows to once a week or so. We needed an alternate source of water without running a county water line from the house to the barn.

To augment the rainwater during the more dry months, at first, I installed an inexpensive pitcher style pump on top of the existing well casing. However, the pump I purchased was of inferior quality and the cast iron handle broke in two. This was then replaced with a modern “bicycle pump” style, single O-ring seal pump. This was very dependable but required more strokes than I cared for, to fill a 5 gallon bucket.

To augment the rainwater during the more dry months, at first, I installed an inexpensive pitcher style pump on top of the existing well casing. However, the pump I purchased was of inferior quality and the cast iron handle broke in two. This was then replaced with a modern “bicycle pump” style, single O-ring seal pump. This was very dependable but required more strokes than I cared for, to fill a 5 gallon bucket.

Being an Eagle Scout, “self-sufficient minded” soul, got me to thinking, “could I build a cost effective but dependable solar well pump system?” I began to study the available solar components and low voltage DC well pumps and came to the conclusion that, “Yes, I can do this.”

The heart of my solar well system would be the DC driven pump. I used a tape measure like a “dip-stick” and found that our well casing reaches water at about 12 feet below the surface. Therefore, I decided to place my pump at 20 feet below the surface to “ride-thru” any water table fluctuations. I chose a 12VDC pump capable of 230 “feet of head” while producing 2 GPM at 100 Watts of power draw. This would be more than sufficient to pump the well water up the 20 feet and then the 50 feet of distance to the barn pressure tank. The 100 Watts needed divided by 12 VDC = 8.3 amps. However, since I only need roughly 1⁄2 of the pump’s pressure capability, 4 amps should be all that the pump would draw.

DC Voltage Drop

The normal concern with using low voltage DC is “voltage drop” when there is a considerable distance between the DC source and the DC load (in this case, the well pump: 4A@12VDC = 50 psi). But, since the well casing is within 50ft of my barn where the pressure tank and solar power system would be installed, I decided to skip the complexity and cost of a 24 or 48VDC system in favor of simply using #10 large wire between the barn and the pump. In the end, this limited my voltage drop from 12VDC at the barn, to only 11.8VDC at the pump. Simple tables for calculating your DC voltage drop depending on distance, amperage and chosen wire gauge are available online.

I located my pump– a Nemo 12 VDC submersible pump–which delivers the water flow and pressure I desired while only using 50 Watts of power (4 amps at 12 VDC). This pump begins as a quality “Flo-Jet” brand and then the seller encases it in a PVC tube with sealed electrical connections and long life brushes. This pump only requires a 4 in diameter well casing; luckily, mine came as a 6 in.

I chose #10 “well pump” wire that comes as a 3 wire pair. I used one for +DC, one for –DC and the remaining wire as a ground, connected to earth ground. I used “well pump grade” heat-shrink tubing for insulating my connections at the pump. This type of heat-shrink, when heated, shrinks around the wires but also melts a sealant to keep any water away from the internal splice connections.

I chose #10 “well pump” wire that comes as a 3 wire pair. I used one for +DC, one for –DC and the remaining wire as a ground, connected to earth ground. I used “well pump grade” heat-shrink tubing for insulating my connections at the pump. This type of heat-shrink, when heated, shrinks around the wires but also melts a sealant to keep any water away from the internal splice connections.

Now, you cannot just make your electrical and plumbing connections and then drop the pump down in the well. In our part of Tennessee, the frost line is ~12 inches down, so plumbing is normally buried at 18 inches down for surety’s sake. I rented a “ditch witch” and dug an 18 in deep trench from under the barn out to the pump casing. Next, I went through two metal hole saws to drill an opening in the side of the well casing, 18 inches below the surface. I then installed a “pit-less adapter” in the side of the casing. This serves as the mounting for the pump plumbing and the right angle exit for the plumbing out of the casing and into the 18 inch deep ditch.

I used standard PEX plumbing tubing from the pit-less adapter thru the 18 inch deep trench back to the barn, up and into a corner of the barn floor. I refilled-the dirt into the trench from the well casing to the barn. Finally, I used a few cans of spray foam insulation to fill the open earth under the barn floor.

Next, I constructed an insulated closet for my pressure tank and connected the pump line and tank output line to a frost-free spigot.

The Components

Now to choose solar components. Let us begin with the battery system. Since the pump would draw, at most, 4 amps, I chose a set of 12V gel-cell batteries and wired them in parallel. Each battery is rated to produce 35 AH (35 amps for one hour) which you can use however needed. So, wired in parallel, these two batteries can provide 70 amp hours at 12VDC. Take 70 amp hours and divide by the pump draw of 4 amps, resulting in 17.5 hours of pump run-time. My pressure tank holds 20 gallons. Take 20 gallons divided by the pump’s 2 gallon per minute flow rate, resulting in a 10 minute run-time to refill the tank, starting the fill cycle from completely empty. In other words, I have more battery capacity than needed to refill the 20 gallon tank once per day. This leaves plenty of spare battery capacity for other items like security lighting, livestock fans during the summer as well as DC power tool charging etc.

Now to choose solar components. Let us begin with the battery system. Since the pump would draw, at most, 4 amps, I chose a set of 12V gel-cell batteries and wired them in parallel. Each battery is rated to produce 35 AH (35 amps for one hour) which you can use however needed. So, wired in parallel, these two batteries can provide 70 amp hours at 12VDC. Take 70 amp hours and divide by the pump draw of 4 amps, resulting in 17.5 hours of pump run-time. My pressure tank holds 20 gallons. Take 20 gallons divided by the pump’s 2 gallon per minute flow rate, resulting in a 10 minute run-time to refill the tank, starting the fill cycle from completely empty. In other words, I have more battery capacity than needed to refill the 20 gallon tank once per day. This leaves plenty of spare battery capacity for other items like security lighting, livestock fans during the summer as well as DC power tool charging etc.

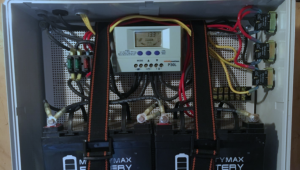

Next, we need solar panel(s) and a charge controller, all installed in a simple enclosure with a few system fuses and ON/OFF switches. In order to re-charge the 70 amp hours of battery capacity from a half discharged level, we would need to supply 35 amp hours of energy from the solar panels. The charge controller is used to “smartly” supply the 35 amp hours of energy to the batteries in a controlled charge manner, all while handling the solar panel power output that varies with the behavior of the sun due to rise/set/ clouds etc. on any given day.

Next, we need solar panel(s) and a charge controller, all installed in a simple enclosure with a few system fuses and ON/OFF switches. In order to re-charge the 70 amp hours of battery capacity from a half discharged level, we would need to supply 35 amp hours of energy from the solar panels. The charge controller is used to “smartly” supply the 35 amp hours of energy to the batteries in a controlled charge manner, all while handling the solar panel power output that varies with the behavior of the sun due to rise/set/ clouds etc. on any given day.

Amp Hours and Watt Hours

Now 35 amp hours roughly equals operating a 35 watt device for one hour. Therefore, it would be safe to pick a solar panel with as small as a 10 watt output (requiring 3.5 hours of charge time). However, I always over-design plenty of capacity in any electrical or mechanical system. So, I chose to install two 100 watt solar panels in parallel which then offer up to 200 watts of charging power to the batteries via the charge controller. This gives me plenty of over capacity of solar panel power for any future additional power needs as well as plenty of “cloudy winter days” re-charging. I built a simple wooden frame and mounted the two panels on the barn roof. I ran the wiring thru PVC conduit back into the barn control panel.

Now 35 amp hours roughly equals operating a 35 watt device for one hour. Therefore, it would be safe to pick a solar panel with as small as a 10 watt output (requiring 3.5 hours of charge time). However, I always over-design plenty of capacity in any electrical or mechanical system. So, I chose to install two 100 watt solar panels in parallel which then offer up to 200 watts of charging power to the batteries via the charge controller. This gives me plenty of over capacity of solar panel power for any future additional power needs as well as plenty of “cloudy winter days” re-charging. I built a simple wooden frame and mounted the two panels on the barn roof. I ran the wiring thru PVC conduit back into the barn control panel.

Once I had everything connected, I allowed the charge controller to charge the batteries to full capacity and then turned on the pump. Only 10 minutes later, I had a full 20 gallon pressure tank of water!

All I can say is, “there’s not much better than free, clean, cold well water.” From this one project, we have established an alternate source of pressurized water and electricity, all completely off- grid, with not a single tie to any other authority. The beginnings of our journey to self-sufficiency.

NOTE: Always have any natural water source tested for use as potable water.

System Cost

My total component cost was less than $650 USD. One could build the same system using a 30 Watt solar panel and a single battery for less than $500 USD. Yes, our home is still supplied county water and coop electricity for “normal life.” However, should things go awry, we now have multiple water sources and off-grid power, not to mention “a sense of accomplishment and empowerment.”

This system has been online for more than four years now without any component failures. I have also added 12VDC motion sensor security lighting, inside overhead lighting and fans for the livestock.

Very cool. Well thought, engineered, and built.

Thank you kindly. My wife was born in Cincinnati and we visit her relatives in Middletown.

Thank you; it was a very fun endeavor.

This is very encouraging. I always thought it would take a massive solar build out to run a well pump. Thanks!!

The thing to remember is you don’t need a 24/7 constant flow of water. You only need to refill a pressure tank for future use. So, low flow like 1GPM (60gph) is plenty to refill a pressure tank a few times a day. That allows the use of a low flow, 50psi pump (low power draw). Use “100 vertical feet of water pumping requires 45psi”

Very nice project, please keep us apprised of developments. But, “two is one and one is none”, so don’t give up on your manual pump. Can you give yourself a longer/stronger handle with steel pipe to give yourself more mechanical advantage and an easier time?

Yes on “one is none.” I still have my modern stainless bicycle style pump and PVC sections stored securely as my backup package in the spring house.

Great job! What prevents your battery from discharging too low? Thank you

Hello Michael, I’m using a “Windy Nation” charge controller. It will disconnect the load were the battery bank ever fall below 11VDC.

Thank you! I am also using a Windy Nation 100 watt panel and charge controller, however, my water 12VDC pump is connected straight to the battery, so not sure how to monitor that part.

thank you

The Windy Nation controllers have 2 screws for PV “IN”, 2 screws for “BATT” and 2 screws for “LOAD”. Your pump should Not be connected straight to the battery. It should, instead, be connected only to the “LOAD” screws of the controller. This allows the controller to “control” when the battery is connected to the load and when it’s disconnected from the load.

I have a well that is currently at 75 feet with another 20 foot run to the house. Would this system work for this type of set up?

Yes, you would probably wind up with a tank pressure range of ON at 15psi and back OFF at 25psi. The pump came from eBay:

https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F283089991843

Fantastic info, thanks for sharing! Glad to see a “neighbor”, too. I’m on the shores of Watts Bar, so probably not too far.

A’bout 84 miles neighbor. Glad you found the info of interest. I love to learn from and help others.

My well is 100′ deep with about 200′ to get into the pressure tank. I’d love to know what size set up we need. Right now our 1 is the well as it would be about $8k to get county water up here and it’s not in the budget. TY for your reply!!!

Hello Joyful Farm, that is outside the capabilities of my system. Not to say it can’t be done. I’d recommend a pump /panel at the well head to pressurize a tank there. Then a second pump / panel fed from that tank to deliver to a second pressure tank at the house.

Thank you PJA for your reply, I truly appreciate it!! I will tell my son and see what he can find for us. As we know 1 is 1 and 1 is none. Right now we’re at the 1 is “none” if an emergency happens.