Yesterday, we started looking at the Ghost Gunner, running it through its paces and turning out the first completed lower starting with an 80% completed unit. Today, we’ll finish up that review and look at the problems we encountered while running the machine.

First Completed Lower

The only real test of the Ghost Gunner is whether or not a decent trigger control group fits in the receiver after that first lower is completed. I’m happy to report that, yes, it does. This receiver wasn’t as fulfilling to make as my first one on a milling machine (using a Tactical Machining lower and milling template), but it was sure a lot faster and easier. When you look at the finished product, you can see milling marks (lots of them) because the machine takes such small bites. However, all such marks are interior to the receiver. Furthermore, while cosmetically not pleasing, they make no difference to asthetics of the assembled firearm and do not impede the function. If you are a perfectionist, I suppose you could remove them with some careful filing, but I chose not to go to this extra, unnecessary effort.

The only real test of the Ghost Gunner is whether or not a decent trigger control group fits in the receiver after that first lower is completed. I’m happy to report that, yes, it does. This receiver wasn’t as fulfilling to make as my first one on a milling machine (using a Tactical Machining lower and milling template), but it was sure a lot faster and easier. When you look at the finished product, you can see milling marks (lots of them) because the machine takes such small bites. However, all such marks are interior to the receiver. Furthermore, while cosmetically not pleasing, they make no difference to asthetics of the assembled firearm and do not impede the function. If you are a perfectionist, I suppose you could remove them with some careful filing, but I chose not to go to this extra, unnecessary effort.

GG Lower vs. Others

The early-production 80% lowers from Defense Distributed have more surface machining on them. (The more recent ones have bead blasted exteriors for a much more smooth appearance.)These were not the only ones that have this level of machining, but lowers like Tactical Machining’s are obviously from a more advanced mold with not much exterior machining, as you can see in the photos. The corners are more rounded and the surface is a bit rougher but with no machining marks. With the TM lower, you can pretty much finish the job with little more than a file to remove burrs and end up with a clean, cosmetically clean lower, ready for anodizing. The GG lower requires more surface preparation to remove the machining marks. Both are excellent lowers.

The early-production 80% lowers from Defense Distributed have more surface machining on them. (The more recent ones have bead blasted exteriors for a much more smooth appearance.)These were not the only ones that have this level of machining, but lowers like Tactical Machining’s are obviously from a more advanced mold with not much exterior machining, as you can see in the photos. The corners are more rounded and the surface is a bit rougher but with no machining marks. With the TM lower, you can pretty much finish the job with little more than a file to remove burrs and end up with a clean, cosmetically clean lower, ready for anodizing. The GG lower requires more surface preparation to remove the machining marks. Both are excellent lowers.

Receiver Jig Modification

The downside to the non-GG lower is that, as we noted yesterday, you may have to modify the jig. The TM lower had more material around the bolt catch pivot and around the rear takedown pin clearance near where the buttstock attaches. I had to make a trip to the hardware store to purchase a small burr bit for my Dremel, which made modification of the jig easy. Slow is the name of the game, when making these modifications though. Take just a bit off where the jig impacts the receiver in the wrong place, then trial fit again. If you take too much off, you weaken the jig and have to start over with a new jig.

Speaking of the jig, the Ghost Gunner comes with the files needed to 3D print the jig parts on a standard 3D printer. You can either print your own, if you have access to a printer, or you can purchase another jig from Defense Distributed. But don’t get the idea that the jigs are fragile. They are adequate for the stress that they are put under.

Speaking of the jig, the Ghost Gunner comes with the files needed to 3D print the jig parts on a standard 3D printer. You can either print your own, if you have access to a printer, or you can purchase another jig from Defense Distributed. But don’t get the idea that the jigs are fragile. They are adequate for the stress that they are put under.

Repetition

At this point, it is just a matter of how many receivers you want to finish. If you do more than one, you will need a decent shop vacuum to clear the milling chips. I let them fall through the bottom of the unit and pile up, but then I had to vacuum them up about every third receiver. In between receivers, I brushed the loose chips off of the mounting plate and from any moving component that I could reach, with a 1-inch paintbrush. You may be surprised at how quickly the chips build up.

I was on a clock, as my wife wanted her dining room table back, so I started cranking them out. In all, I had ten lower receivers that I wanted to run through the machine. One receiver was the Defense Distributed receiver; all of the others were Tactical Machining receivers that I already owned. One thing to note is that you must have receivers that have the notch already milled in the rear takedown pin area. I have several older receivers that do not have that area machined, and they will not be completed. I will have to finish those receivers on my mill.

I was on a clock, as my wife wanted her dining room table back, so I started cranking them out. In all, I had ten lower receivers that I wanted to run through the machine. One receiver was the Defense Distributed receiver; all of the others were Tactical Machining receivers that I already owned. One thing to note is that you must have receivers that have the notch already milled in the rear takedown pin area. I have several older receivers that do not have that area machined, and they will not be completed. I will have to finish those receivers on my mill.

Failure!

By the ninth lower, I was no longer paying attention to the Ghost Gunner. I loaded the lower in it, followed the prompts, and walked away until it needed my attention again. The droning of the machine was very hypnotic. That was a good thing, because regular conversation was difficult around it. Then, I loaded the tenth and last of my lowers into the machine and walked away. After about an hour, suddenly I heard a loud bang, and the whine of the machine changed.

It was no longer cutting, but the motor was running without any load. I ran over to it and peered inside. Sadly, what I found was that the spindle of the machine had sheared off. Since I wasn’t actively looking in it, I had no idea what had happened. This was on a Friday at about 8:00pm, so the machine sat idle the entire weekend while I waited for regular business hours on Monday.

According to Defense Distributed, this happened occasionally and no one really understood why. The tech informed me that I could send the unit back to them and they would repair it, or they could send a new spindle to me along with instructions on how to repair it. I chose the latter. I received the spindle in less than four days, but by then life had moved on. My wife demanded her table back and the unit had been boxed and moved to the garage. I just put the new spindle on top of the Ghost Gunner in the garage and decided I would look at it later.

Back to GG

You know how “later” goes, so it took a while to get back to the Ghost Gunner. A full year later, I pulled the machine off the shelf and decided to tackle the spindle change. I now had a working shop, so I wouldn’t be invading the kitchen or dining room this time. When I looked online, the instructions for changing the spindle were no longer there. No problem, I thought; I’ll just wing it. As I sat there staring at the machine, trying to remember the intricacies that the tech had told me about, I decided it might be a good time to call the manufacturer and request access to those videos again.

What I learned was that I was never supposed to have received that spindle. They wanted the unit back for repair. Since I had the spindle, I wavered on sending it back, but in the end chose to oblige. When we bought this unit, Defense Distributed was on the verge of upgrading the spindle to a much stronger, more accurate one. The unit in my possession was a version 1.5. It already had the upgraded power supply but the old spindle. Since the new spindle was so much better, I just decided to send it back in and have it upgraded to version 2. It’s a good thing I kept all that packing material and the original box! One bonus is that the version 2 can also handle AR-10 and M1911 80% lowers,

What I learned was that I was never supposed to have received that spindle. They wanted the unit back for repair. Since I had the spindle, I wavered on sending it back, but in the end chose to oblige. When we bought this unit, Defense Distributed was on the verge of upgrading the spindle to a much stronger, more accurate one. The unit in my possession was a version 1.5. It already had the upgraded power supply but the old spindle. Since the new spindle was so much better, I just decided to send it back in and have it upgraded to version 2. It’s a good thing I kept all that packing material and the original box! One bonus is that the version 2 can also handle AR-10 and M1911 80% lowers,

Three weeks later, I had the new v2 unit on my doorstep.

Is It Worth It?

The question of whether it’s worth it obviously depends on your own current thinking. In today’s market of oversupply, where you can pick up a completed AR pattern rifle for $500, it’s hard to justify this sort of expense just to obtain a no-paperwork rifle. However, most of those serialized firearms do actually have a paper trail; it’s just really difficult to follow. Even if you purchase a used one with no bill of sale generated, the seller still has a name that he can give. Anyone who sells a firearm without some form of ability to pass the buck if/when the ATF comes a knockin’ is just asking for trouble.

Where the Ghost Gunner shines though is when you are wanting more than a few rifles. If you purchase 30 80% lowers, no one takes notice. But if you purchase 30 serialized 100% receivers or completed rifles, some people start noticing. You can always purchase them one at a time, but then you end up with 30 different unmatched rifles. Having parts commonality is nice, when it comes to gunsmithing.

Forget Spreading the Cost

Forget about the idea of spreading the cost among a group though. Like it or not, the ATF has its own interpretation of the law, and they have determined that a group cannot buy and share this machine. You’re not even allowed to rent it from someone who owns it. Right now, the best strategy is for a person to buy it outright, make their planned number of lowers on it, and then sell it for $200 less then they paid for it. The next person can do the same thing.

Defense Distributed does not care who owns the machine if it needs repairs or parts. They don’t ask for an original receipt either. If you need it repaired, you just call them and get it approved to ship back to them where they fix it and ship it back to you. With this strategy, you can easily pay for the machine with a reasonable fee for each person whose hands it passes through, and it’s functionally the same.

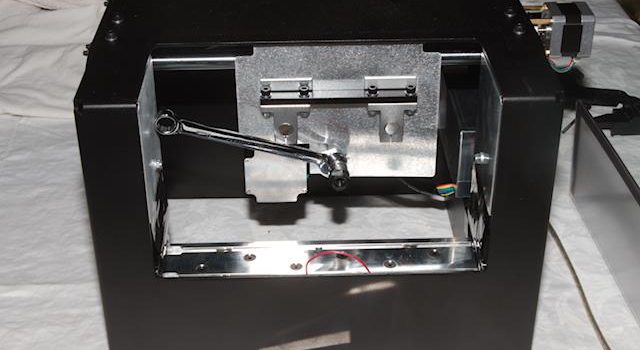

A Fully Functioning Hobby CNC Milling Machine

Note that this is a fully functional hobby CNC milling machine, and there is no reason you can’t develop your own code and make other things on it if you so desire. I didn’t go down that road though. Since I own a full-sized lathe and milling machine, I don’t need a hobby machine.

Bottom Line

If you already have a milling machine (or a heavy duty drill press) and a little bit of mechanical dexterity, you are probably better off buying 80% lowers and one of the template plate kits to manufacture your own receivers. Perhaps you like the idea of mounting the receiver and pushing the button, waiting three hours, and then having a completed lower. You may want to look at the Ghost Gunner then. If you do decide on a Ghost Gunner, buying with the intent to resale is probably your best bet.

In all, the strongest point that the Ghost Gunner has going for it is the symbolic digital gesture it throws at gun control. It’s hard to put a price on that. Yes, it’s expensive now, but we are still in the early development stages of CNC and 3D printing. By purchasing one of these units (even if you buy it used and pass it on when you are done with it), we guarantee that companies like Defense Distributed will continue to develop the industry. So yes, I’m happy with it.

When did you originally buy your GG CNC machine?

From the first article, it seemed that you had bought it recently, within the past 6 months or so.

From the second article, now I read that you’ve had it for at least a year.

Just curious. There may be changes to design, cost, availability, new model releases, that would be good to be current on.

I was looking for one of these when I found a company called BROKEN ARMORY. It was more in my budget. I got a jig, all tooling and an 80% lower for $300. I thought “what the heck, it’s worth a try”. It worked wonderfully! I was amazed at the quality of the design and material used. I built my first lower and it was super easy but it does take more labor than the GG. (4 hours for my first one) and you need a drill press. The tool was such good quality that I have since sold it to friends (for $1) and bought it back when they were done several times. I would gladly recommend this product to anybody with a drill press. (no, I have nothing to do with this company). The most amusing thing about this company is that they are out of Kalifornia!!!! But they have a great product. I wonder how long before they relocate to Idaho or Texas.

P.S. They also do 308’s

I checked out the BROKEN ARMORY website. I just tickles me that they are in Commiefornia.

There was a particularly good article on CNC machining from one’s garage Titled “3D Printing: Is it in Your Future?, by Kevin L.”

Can we get him back on the horn to give us an update from the front lines?

This is very interesting to me.

Link: https://survivalblog.com/3d-printing-is-it-in-your-future-by-kevin-l/

Was the tooling included,extra or standard(available from multiple sources ) is other tooling available?

The unit that we received had the basic tooling for an AR-15 pattern receiver. Everything except the receiver was included. Other tooling is available on their web site.

Quick followup, Hugh.

When you received the GG2, did you also get the tooling and software to make 1911s, Glocks, and AR-10s?

@BobW,

No. When we bought the original unit, it only did AR15s and that is the tooling that came with it. Defense Distributed does sell the other tooling/jigs on their website though. If you buy one used, you just sort of get what comes with it. If you order a new one, you can order it as you like. for the used, DD will sell you the tooling for it. I believe you can print the jigs on a 3D printer or buy them from DD.

Now the GG2 has upgraded power supply/spindle/ and more room to do AR15/10 AR9 Glock/1911/sig and some other things in the works. You can do regular AR15 mill avg time is 2hrs to complete or you can do M4/M16 mill avg time 4hrs to mill. Now it does not matter if you have the rear pocket already milled out or not. The stock file the comes with the GG require the rear pocket already be milled out but there is files out there now that do that for you. So it’s not a problem. It takes only 20 min to mill a 1911. I’ve had a lot of fun with it.