Disclaimer

This article covers information and activities that are legal under U.S. federal law and in the author’s state of residence. It is the reader’s responsibility to know and comply with applicable laws in their jurisdiction. Neither the author, nor SurvivalBlog, have any control over readers of this article. This article is therefore for informational purposes only.

INTRODUCTION

“Whether or not you live in England, the right of Free Speech is a universally treasured right, but sadly, a right that is still denied to millions of people around the world.” – Philip A. Luty, as quoted in L. Neil Smith’s The Libertarian Enterprise, April 3, 2005

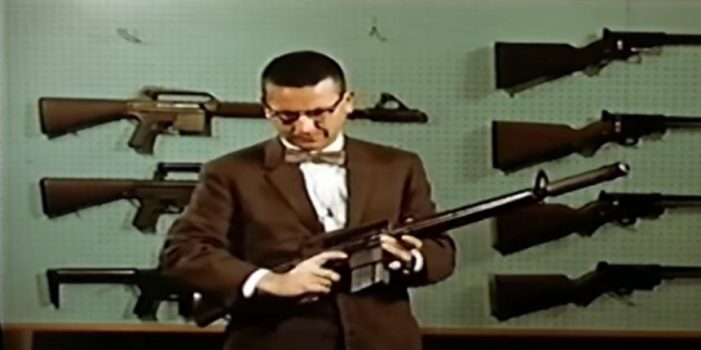

The title of this article mentions printing firearm components, not complete firearms. This is because all designs we will examine utilize some 3D-printed parts, but no firearm that the author is aware of is 100% 3D-printed. All designs use some metal parts, such as springs, pins, screws, firing pins, barrels, bolts, et cetera.

The 3D printing technology that this article will focus on is known as Fused Deposition Modeling, or FDM. It consists of using a computer-controlled “squirter” to lay down layers of molten plastic—building up layer after layer to create a three-dimensional object—starting from a three-dimensional image.

I will not be making recommendations on specific printers, as the available models change frequently as the technology evolves. Rather, I will recommend features to look for in a printer suitable for creating precise, durable parts for firearms, as well as tips for successful printing. I know that the array of printers is daunting. So I’ll suggest a very good website that does recommend specific printers for printing firearm parts.Continue reading“3D-Printed Gun Components – Part 1, by M.B.”