(Continued from Part 1. This concludes the article.)

#4. “Tempered less than Mason jars.” Nearly every book, website, and blog discussing this subject insists that Mason jars are tempered. They’re definitely, absolutely, NOT tempered. Glass has three basic hardening options: tempering, heat strengthening, and annealing. All commercial and home-canning jars are annealed, not tempered. Annealing is a process where jars are cooled down very slowly after production to make them more consistent and to minimize stresses. Whenever glass breaks into the sharp jagged pieces seen when we break a jar or window it’s merely annealed, not tempered or heat strengthened.

That brings up the logical question, are there different annealing processes to make Mason jars stronger than salsa and pickle jars? I contacted another large glass and jar manufacturer who’s been in business for 100+ years. The general manager was kind enough to answer the question himself. Paraphrasing his reply, all the jars they make follow a similar annealing process as do jars made by other manufacturers. He said further, anyone who claims home-canning jars are stronger is using it as a selling tactic, but it’s not true. When I asked if a jar is a jar, he replied yes, basically a glass jar is a glass jar.

#5. “ [commercial jars] may be weakened by repeated contact with metal spoons or knives used in dispensing mayonnaise or salad dressing. Seemingly insignificant scratches in glass may cause cracking and breakage while processing jars in a canner.” More pure conjecture and there’s no data to support it. Manufacturers put a tin-oxide coating on the outside of jars before they’re annealed to prevent scratches by commercial and home canners. I tried a spoon, fork, butter knife, and finally the sharp tip of a Swiss-made steel kitchen knife but I was unable to make a scratch in the glass. Many have experienced the same when scraping label adhesive off commercial jars with a knife. Chips in the rim are possible but it seems a rounded jar rim would be less damaged during use than a flat rim with its right angles at the edges which could more easily be broken off.

Canning Lid Shelf Life – Even though companies such as Ball recommend using lids within a year of purchase, they concede they can still be used 3-5 years later. The USDA Complete Guide to Home Canning, p 1-15 says, “Gaskets in unused lids work well for at least 5 years from date of manufacture. The gasket compound in older unused lids may fail to seal on jars. Buy only the quantity of lids you will use in a year.” Again, no experiments with data have been done on this. Many of us know from experience that modern lids have a much longer shelf life than five years. For his article, I dug through my stash of used lids and found one from 2007 and several from 2008 and 2009. I reconstituted them in hot water and when placed on jars of boiling water, all sealed. All my commercial pickle and salsa jars were bought prior to 2013 and still continue to seal every year.

DIFFERENT TYPES OF PLASTISOL LID SEALANTS

I mentioned above that I haven’t tried reusing commercial jars with pressure canning. I found a supplier who explained there are three types of plastisol sealants used in jar lids. Many one-piece Mason jar lids sold online specify, “not for canning.” Those have “standard plastisol” and are used for everything imaginable, but for canning have only “hot-fill and cool” applications where the jars aren’t boiled afterwards. “Pasteurization plastisol” is mostly used on lids for commercial steam canning where the temperature doesn’t exceed 212°F and can also be used for water-bath canning. The third type is called “retort plastisol,” retort referring to pressure canning where temperatures will be in the 240-250°F range. Since commercial canners only use pasteurization processes in their canning, many of the commercial-jar supplier websites indicate they don’t offer tort lids “but we can get ‘em!” Home-canning two-piece lids use tort plastisol so they work equally well for pressure canning, water-bath canning, and hot-fill-and-cool applications.

In a lengthy phone conversation with the U.S. rep of a European jar and lid manufacturer, he confirmed the different types of plastisol sealants for different heat tolerances, and also mentioned the red color of tort lids is merely a colorant. Concerning reusing lids, he said he couldn’t recommend anything one way or the other but tells customers who ask if they do reuse lids, try it first and if it works then be sure to do it the same way every time.

MORE RESEARCH AT HOME

After learning that Mason jars are not tempered, I did a little measuring and experimenting at home to compare the properties of different sizes and brands of both canning and commercial jars.

Jar Wall Thickness – I broke one of each of my 11 sizes and brands of canning and commercial jars and using calipers accurate enough to measure the width of a human hair (1/10th millimeter), I measured the thickness of the glass. The variation within each jar turned out to be extreme. You can see the distortions by holding a jar against the light, then rolling it in your hands. Ball pint jars varied between 1.85 mm and 3.20 mm. With the thinnest part of the jar being the weak point, the 11 jars I tested all had about the same wall thickness.

Jar rim widths were fairly consistent on any given jar but as already discussed, rim width has no bearing on the ability of the lid to seal.

Reconstituting Jar Lid Sealants – In addition to the photos I provided in the original article on reusing jar lids, I did more extensive research in my kitchen and on the internet on what exactly happens chemically and physically when lid-sealant plastisol is heated and reconstituted. One lid manufacturer replied that nothing changes chemically when plastisol sealant is heated and reheated but physically, heat and moisture soften the plastisol. Nobody explained exactly how the seal reconstitutes but perhaps reheating expands the air pockets seen in the cross section photos below? This maybe explains why some of my oldest used lids have only very shallow impressions, the sealant relaxing and the air pockets possibly having re-inflated with the passage of years in storage.

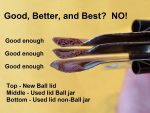

Photo 4 shows the same piece of lid sealant in cross-section from a commercial pickle jar lid I have reused six times canning my own pickles. After heating in water the pasteurization-plastisol sealant has almost reverted back to its like-new condition. While the indentation hasn’t fully disappeared, remember there’s no “good, best, and better,” only “good enough.” Even the untreated lid still has more than enough cushion to make a seal.

Photo 5 demonstrates this concept using home-canning lids with tort-plastisol sealant. A new Ball lid, and reused lids from both a flat-rimmed Ball jar and a curved-rim generic jar. All three have plenty of room for compressing the sealant to make a tight seal so all are good enough, not good, better, and best.

Photo 5 demonstrates this concept using home-canning lids with tort-plastisol sealant. A new Ball lid, and reused lids from both a flat-rimmed Ball jar and a curved-rim generic jar. All three have plenty of room for compressing the sealant to make a tight seal so all are good enough, not good, better, and best.

Mason jars once came with the lids packaged separately in a flat pack on top of the jars. Now, the screwed-on lids arrive with a dent in the sealant. I wrote to the Newell Company, maker of Ball/Kerr canning jars, asking about the lid dent. Newell’s customer service rep was very knowledgeable and courteous in answering several e-mails. She said heating the lids on low for 10 minutes or less would be enough to diminish any impressions the new jars leave in the sealant. Logically, if heating new lids can diminish sealant impressions it can also do the same for used lids, even if not as fully. I and many others know from years of personal experience that not only does this work to revive new lids, but used lids as well. Again, there isn’t good, better, and best, only “good enough.”

The Newell rep also mentioned the new sealant formulations don’t require lids to be preheated. The same can be true with used lids as well. In the first article I mentioned my yogurt-making jars (recycled salsa jars) and their lids have resealed 52 times but failed to mention that was without preheating the lids. The room-temperature lids are screwed in place onto jars containing 120°F re-pasteurized milk, then slowly cooled while the yogurt cultures do their job.

For those wishing to do another simple used-lid sealing test, the next time you make a large batch of chili or pasta sauce use the “hot-fill and cool” process mentioned above. Bring the chili to a temperature above 185°F, immediately ladle it into cold jars, wipe the rims, put unheated lids on, and after cooling put them into the refrigerator for eating over the next month. My lids always seal and I’ve reused those same ten wide-mouth lids and Ball jars countless times.

FOOD INDUSTRY AND HOME CANNING EXPERTS

My personal conclusion, and this is conjecture on my part, is that the USDA’s recommendations, “a consensus among food industry and home canning experts,” were based on a few things.

First, some of the food industry and home-canning experts undoubtedly included Mason jar and lid producers such as Ball, a name synonymous with home canning. For many foods, the biggest home-canning expense is rebuying lids every year. For home-canning supply companies, there’s no benefit if people are reusing lids. Mason-jar manufacturers don’t want a one-time sale selling you a case of jars, they want your repeat business buying new lids every year. You certainly can’t blame them and there’s nothing dishonest or deceitful about them saying, “We don’t recommend…”

Second, with many lawsuits in the U.S. for the most inconsequential things, commercial jar and lid manufacturers defend against liability by saying “We don’t recommend.” Jar makers won’t say commercial jars are reusable since they too have nothing to gain. They merely want to sell a jar to the pasta-sauce company without future liability problems from home canners. Also, in many cases, they’re the same companies who make Mason jars and would rather you buy their canning jars instead.

Conclusion

Now that the science behind the “why” has been explained, I hope during future canning-lid and jar shortages as we experienced in 2021/2022, more people will rethink reusing jar lids and for the frugal, save money pre-SHTF. Secondly, that they’ll begin saving used lids in their TEOTWAWKI prepping. A 15-ounce vegetable can holds 66 lids, taking up very little storage space, and they’ll be one heck of a barter item after the crash. For those still afraid to reuse canning lids, Harvest Guard re-useable lids are the best option for TEOTWAWKI planning.

While I find the “why” fascinating, it doesn’t change my personal experience and knowledge gained over the past umpteen years reusing lids as well as commercial jars and lids. As mentioned in the first article, during shortages when you can get a dozen pint-and-a-half jars of pasta sauce at Aldi for $10.20, the same price as Mason jars, it seems crazy not to take advantage of the situation. Plus you’re getting 2¼ gallons of “free” pasta sauce in the deal. Keep your Italian ancestors happy by increasing your intake of tomato sauce as I have with my newest recipe, Italian chili. So give some serious thought to reusing commercial jars which you have sets of.

I hope this article has changed some outlooks and happy canning this year!

P.S.: A reader of the first article asked how to remove canning jar lids without bending the edge. I locate where the jar threads are closest to the lid and use the edge of the ring itself to pry the lid off. When the vacuum is too strong to do this without bending the ring, I use the back edge of a butter knife. Using a bottle-cap opener or the tip of a butter knife are the best ways to bend the lid beyond repair.