Welcome to Freeze Dried Friday on SurvivalBlog! We’ve been making so many things in the Harvest Right Freeze Dryer that we want to share some of them with you. If you have something wonderful you’ve prepared in your freeze dryer that you would like to share with SurvivalBlog readers, take a photo of it and send it in along with a description. We might just feature you here! Today we’ll have a quick note about a shaft seal failure. But first:

Keeping the Freeze Dryer Filled

Harvest season is getting close here. Some herbs are just about ready to be harvested, and I can see the garden produce weighing down the plants in the garden. But they just aren’t quite ready yet. So what do you do with you’re Harvest Right Freeze Dryer while waiting for the bountiful harvest to come in?

A trip to Costco (or similar) for their fresh fruit is always an option. Costco is known for their fantastic selection of beautiful fruit, but it comes with a drawback. Unless you are a restaurant or juicing on a regular basis, it’s tough to use it all before it starts going bad. That’s true, unless you have a Freeze Dryer, of course!

Eggs, Eggs, and More Eggs!

Around here though, we have what we commonly call the French toast alert. For those unfamiliar with the term, that is when you know you have an incoming emergency, so you stock up on perishable things that you may not have a chance to get later. These are things that you can generally make French toast with— eggs, milk, and bread. But why wait for the emergency to approach to buy in bulk when you have a freeze dryer!?!

The Bread is covered because we buy wheat berries in bulk from the Bishop’s Warehouse which are processed as needed in our Country Living Grain Mill. The milk and eggs get run through the freeze dryer. A gallon of milk will fit in one batch and is the standard fare when there is nothing else to run. We prefer ours over purchased powdered milk, which is typically non-fat or low-fat. We run whole milk through the freeze dryer, and it reconstitutes and tastes just like fresh milk. The chickens determine when the eggs get run though. They are recovering from the heat and are pouring the eggs on now. When we have more than eight dozen eggs in the fridge, it’s time for a batch to go in.

Shaft Seal Failure

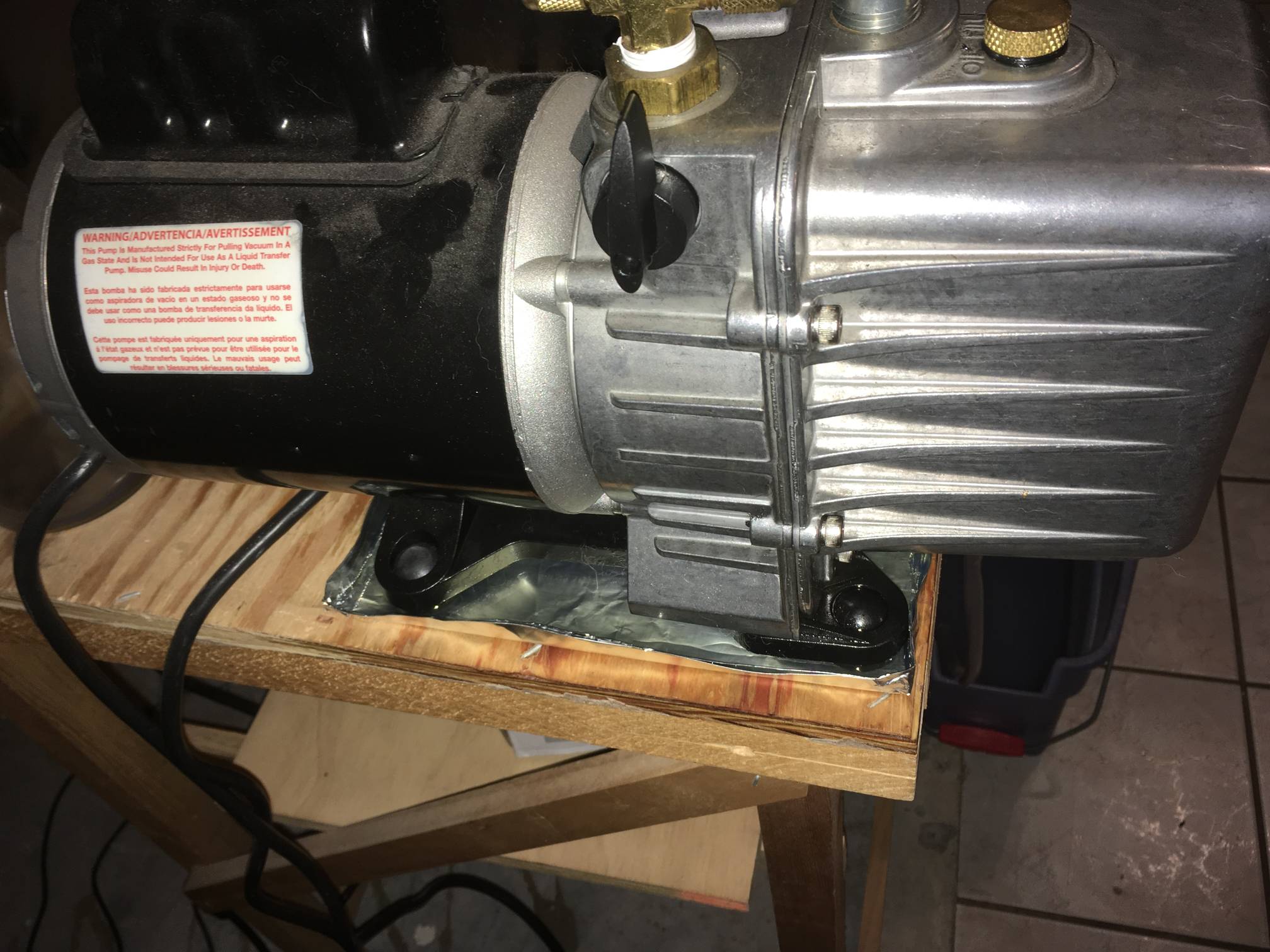

Freeze dryer pump number two is in a failure mode right now. The rear shaft seal is failing and leaks oil, leaving a good-sized puddle every time the pump is run. Sadly, Century Tool is backordered on this particular part and can’t give a time frame on the delivery. In the meantime, the leak is small enough that it doesn’t affect the performance of the pump, and we are able to run a complete batch without the oil level dropping too low. But the mess is something else.

I first tried to cut a milk carton to fit under the pump to catch the oil, but I soon realized that it wasn’t large enough. The pump feet flattened it out, allowing the oil to run freely on the table. Then it hit me. My wife uses the commercial heavy duty aluminum foil in her kitchen. I just snagged a piece just a bit larger than the pump foot print. A couple of folds later, I had an aluminum trough with a 1/2-inch rim to contain the oil mess while the pump runs.

It’s not pretty and it certainly isn’t durable, but nobody messes with the pump. The foil is strong enough to work as a temporary trough. After about three runs of the machine, I simply drain the oil into the oil filter along with the other used oil and it gets recycled back into use. It’s simple, inexpensive, and effective. I may keep that trough under the pump all of the time as a “just-in-case” sort of thing.

I have never worked a freeze dryer before but being a HVAC tech I am framiliar with vacume pumps. https://www.amazon.com/JB-Industries-DV-T1-Vacuum-Caddy/dp/B015Y9MPX6

This will not fix the leak but it may be a good backup safty. In case of a catostrophic leak this drain pan should hold a pumps worth. (Makes oil changing less of a bear also.

I actually thought about that pan for a couple of minutes. Sadly, there isn’t enough room on the table that the FD sits on. It would have been nice though.

It’s always a good idea to stock spare pump parts and even a spare pump.

Perhaps I missed this, but a freeze drying uint is not a piece of equipment that I am familiar with – in comparison, I know all about what I would use to assemble an AR-15 – finish, barrel length and twist rate, NIB coatings, M-LOC rails, etc.. Where does one find a freeze drying unit? What features should it have? What is a reasonable price for one? Who makes a Glock/AK-47 reliable one?

Harvest Right makes & sells freeze dryers for home use (www.harvestright.com). They are all pretty pricey, but if you have a group of preppers the cost might be managable. I’ve also heard that used units can sometimes be found on Craigslist and ebay. Unfortunately, from the things i have heard, although not experienced first hand, none of the units are Glock/AK-47 reliable.

Got two HR freeze dryers, thinking of getting a spare pump as well. Was advised recently by HR to remove the splash plate as that seems to be a particular area of generating rust debris and apparently the pump runs fine w/o it. Just processed 4 trays of cabbage – beautiful ! Will enclose a pic. next time !

Look forward to your Friday notes re: HR freeze dryer .

@ron,

The pump will run fine without the splash plate, but you can’t open the fill valve and put more oil in while it’s running. That is usually not a concern, but since mine leaks right now, we do want that ability. It’s a simple part and I have seen people replace it with a piece of aluminum or stainless steel.

Careful reading from J.B. Enterprises will reveal that they expect the oil to be removed and replaced after every use because of the water issue. I’m finding that recycling the oil is working well. You just let it sit for a day or so after removal to let the water separate out and then filter it.

Have a HR freeze dryer also and wanted to know when u drain the oil after each use to let the water settle out, do u use the purge method by running the pump motor during oil drainage or do u just open the top plug and bottom plug and let it drain by gravity naturally?

All of our storage jars are Kerr/Ball wide mouth jars. Somewhere along the line, I acquired a lonely quart standard mouth jar. Nobody likes it so I inherited it. I use it to drain the oil while it is still hot from the pump. Basically, when the FD quits it’s cycle, we put the food away in wide mouth jars. I then let the oil drain by gravity into the standard mouth jar and let it sit.

The reason I like this jar for that job is because a standard mouth jar has a significant shoulder on it. When you pour the oil from this jar into the gravity filter, you can see the boundary between the oil and water and you just pour until you almost reach the water, then stop. After you have done this 4 or 5 times, there is a significant amount of water in the jar and you can just drain that as you would dispose of it. It’s pretty efficient.

By draining the oil from the pump while it is hot, it keeps the chamber of the pump pretty clean. Since I’ve adopted that, the sight glass has never gotton gross and we don’t have to purge the pump anymore. I’ve just been doing that for this last year, so we’ll see how things go long term.

Thank you so much HJ. Your info has been very helpful. The site gauge visiability is a real problem too so I will be doing what you suggest. This can save me quite a lot on oil purchase too.

Thank goodness I saved all my used oil to use as lamp oil in case of an emergency. Now I think I can pour that into a glass container thru a filter & possibly reuse some of that oil.

These pumps are pretty durable. I don’t think a whole spare pump is required if you have just a few key parts to rebuild it. It would cost far less. As soon as the parts come in, I’ll document the rebuild for the blog.

Howdy, a freeze dryer is not in our current budget. We use a dehydrator from Cabelas. 80L in size for 400 bucks. For our abundance of eggs this is great. Scramble them up, pour in pans, and dehydrate at 135-145 degrees for 14-16 hours, then Fine POWDER them up. Reconstitute 1 tablespoon of eggs with 2 tablespoons of MILK for best results.

Sasquatch, we’re in the same boat. No freeze-dryer for us either. What resources have you used to learn how and what to dehydrate, and then how to use what you’ve dehydrated? Any good books? Trial and error? I’m sure the possibilities are endless and I haven’t thought of most of them.

@sasquatch,

You’ll find the difference between Freeze drying and dehydrating is similar to the difference between canning and freezing.

You can can nearly anything, but the taste, texture and appearance on most foods get muddled. However, some things work better canned than frozen.

Here at the Latimer homestead, we prefer our sauces canned because the flavors blend much better. They typically need some time to sit together over time to achieve the desired flavor. Freezing it keeps it from doing that. We do occasionaly freeze dry sauces so that we have some to take on a trip.

Likewise, fruit usually works much better in a dehydrator than a freeze dryer.

Things that should have a chewey texture are better dehydrated. If you want things to reconstitute fast, freeze dried is better, but your end product will by like you froze it, then thawed it out. Things that you cook with are just fine this way, but things that you just want to eat are not. You will often find that you have to eat the freeze dried product in it’s dry form. (Ice cream and mil come to mind)

In any case, a freeze dryer is not a necessity and I certainly wouldn’t go into debt over it. But it is nice to have. Might be something you would consider putting $50/month into an envelope for though.

Finished FDing the last of 40 pds of hamburger. I now know that one 10 pd roll will fit in 4 trays if I put them in a square paddy size and shape. Browning the paddies in the skillet first reduces size and drains what little fat is in the 97/3%. It took 32-36 hours for each run but the HB came out perfectly. The 4 trays of FD hamburger will fit in two 1-gal mylar bags much easier than in canning jars; however, the bags appear to take up more storage room. Next week I start FDing chicken breasts and eggs.

Thanks for the info on the pump; I’m not a mechanic but the schematic looks plain enough to do basic repairs. Stocking an extra pump, while important, is out of reach for a while. Since my FDer is new hopefully the pump will last with good maintenance.

The rear shaft seal didn’t go out until after three years of heavy usage and we didn’t always treat it well. It was a learning curve. I suspect that a well maintained pump running with fresh or recycled oil on every batch will last for many years without issue.

I do keep multiple seals on hand for my pumps because you never know when you may need to open it up. This year I purchased one spare vacuum cartridge as a just-in-case (about $200). If the motor itself dies, we’ll just have to see. Most motors can be rebuilt. In a SHTF situation, I doubt we will be running the freeze dryers because of the electricity required.

Not sure what the cfm requirements needed on the vacuum system you are running but at my work we use oil less vacuum pumps. It is just an electric motor with replacable graphite vane. As long as you check the vanes regularly for wear and replace them you don’t have any issue. We have pumps that have run pretty much 24/7, except for regular maintenance, for seven plus years without issue.

I haven’t seen any vacuum pump except an oil pump that can pull the vacuum needed for freeze drying. Before the Harvest Right, I played around with several different types of pumps and all but oil pumps failed to pull the necessary vacuum. It’s actually not about the CFM, but about how deep a vacuum you can get.

I have the mid size unit. There is some work involved in running a batch of food but is very manageable. It is less work than setting everything up to pressure can I think. If you are into prepardness though I feel this is a must have. It is amazing the foods you can preserve with it. I have pork chips running in mine right now. I have also had the rear seal go out of my pump at about the one year mark. I placed a aluminum pan under it and kept running. Harvest right sent me a new pump no questions asked. I still keep the pan under it just in case. It was quite messy when the oil leaked. They are worth it even with the little work involved in running them. Just my opinion .

I was shopping for a Harvest Right and had many discussions with an “Engineer” (not sure of credentials) when they were just hitting the market a few years ago. At the time there were discrepancies between what the sales folks were saying and what the engineers were saying in regards to stable shelf life so I wasn’t willing to foot the bill at that time. They have come a long way, but at that time they had one option that was about $4500.00 installed. When looking at the initial cost, operating costs, and other consumables to use them we decided to just buy freeze dried foods. I am wondering if you still perceive the investment as being worth it over buying staples. Also I am curious if the freeze drier can be used off grid, or if the power drain is too great without external power. I really do appreciate the objective perspective on these.

I consider it a worthwhile purchase. I own two of them. With one freeze dryer, I can turn out 5 gallons of freeze dried food per week. (That is if I pre-freeze food as prep it which requires a dedicated shelf in the regular freezer). That week will cost me ~$10 of electricity and ~$1 of oil. I’ve run one freeze dryer for over 4 years and the other for over 2 years. But lets depreciate it over 2 years and use the full retail price of it (you can generally save $500 to $1000 by buying it on sale). Here is the breakdown for 1 year.

Depreciation of Machine: $2000

Electricity: $520

Oil: $300

Food: $3000

What you end up with is ~260 gallons of food for $5800 or ~$22/gallon.

Commercially produced FD food will cost you somewhere between $40 and $60/gal and you are stuck with what they make rather than what you like. I’ve never seen a Commercial offering that came even close to what Mrs. Latimer makes, yet we can create our own easily.

So yes, it’s is a worthwhile expenditure for us. We actually save much more than that because most of our FD food comes from the garden rather than the stores. After Two years, your machine is paid for and you are making it for even less. Note that I’ve used numbers on the high side here so that there is no question. I believe our actual total costs are closer to about $3000/yr for that amount of food.

We don’t subscribe to the food vault system of prepping so shelf life of FD food is unimportant to us. We store what we eat and we eat what we store. But I have no doubt that the shelf life of low oil foods is easily 25 yrs. High oil foods are probably closer to 10 years. As an example, I have opened vacuum packed FD whole milk that is 4 years old and it taste just like I bought it yesterday.

Yes, you can use it off grid, but you will need a large system to power it.

Also, not sure what you mean by “They have come a long way.” My first freeze dryer is one of their original models and it produces food the same way the current model does. The changes are in how easy it is to use, not in the quality of food it produces. (like the rounded corners on the door so you don’t bang your head on it.) These machines have always produced top quality product at an affordable price.

By “come a long way”, I was referring to what I have read about advances in the control unit being more user friendly, size options, and things like the refining touches you mentioned. When I first heard of them I called them and then met with them to discuss their product. As you mentioned the freeze drying process has not changed in decades, but having one at home was definitely ground breaking. The one thing that was odd to me was that the salesperson said their food had a 25 year shelf life and the engineer said 10 to 15 years. I agree with you that you should eat what you store and store what you eat, so by using what you are freeze drying eliminates the shelf life issue. From following your articles (which are really insightful) the only downside is the maintenance for those not used to maintaining their equipment. Your cost valuations are very helpful as well in comparing costs to buying. I have seen a number of grocery stores getting into the freeze dried food business lately with the newest being Winco. I have not been able to find out where they are sourcing all of their food from, but some comes from countries that I will not buy food from. That also makes an in house freeze drier tempting, not to mention the ability to ‘put up’ what ever you want, and not just what is available.

Thank you for your responses.